Why Stainless Steel Remains a Manufacturing Staple

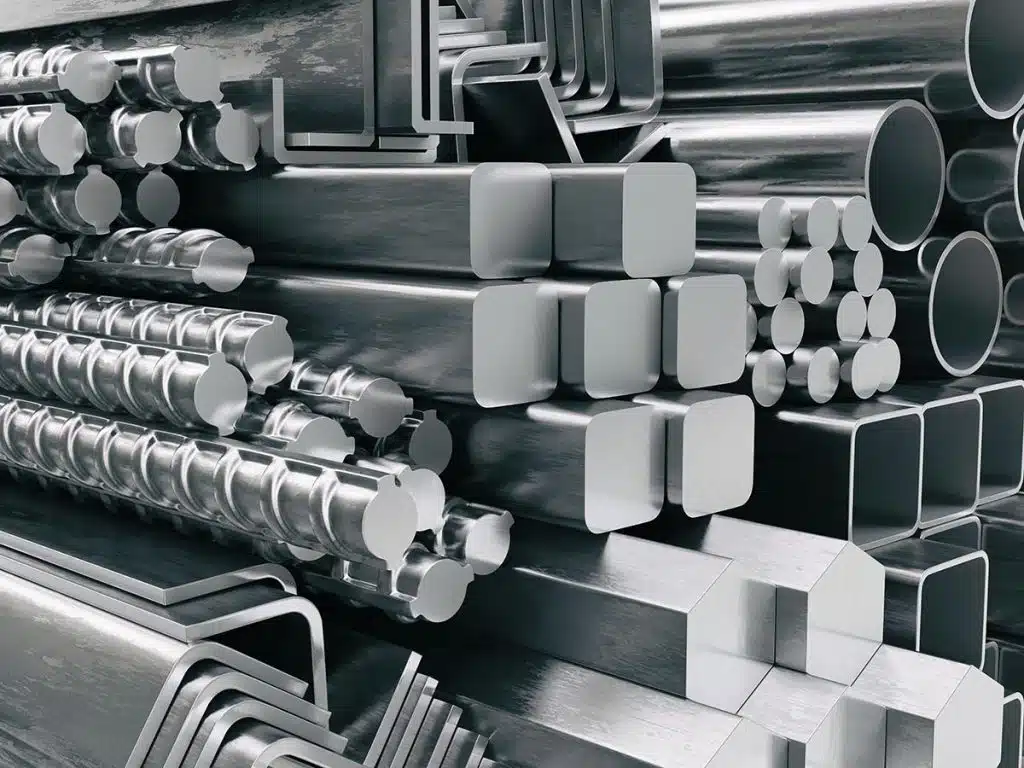

Stainless steel has carved out an indispensable niche in manufacturing due to its remarkable strength-to-weight ratio, resistance to rust and corrosion, and overall versatility. Whether used in food processing lines or towering commercial buildings, stainless steel’s essential traits allow it to meet the needs of high-stakes projects where safety, longevity, and hygiene are non-negotiable. In bustling regional markets, stainless steel products Houston TX, are in constant demand, serving as the backbone for industries that value unwavering reliability and practical performance. Just imagine a refinery or water treatment plant operating without stainless steel—it’s nearly unthinkable given its proven track record at withstanding corrosive environments and daily mechanical wear.

The precision of stainless steel products is crucial for complex systems across the petrochemical, pharmaceutical, and food production sectors. Chemical engineers, architects, and designers count on stainless steel’s ability to resist pitting and maintain structural stability under stress. The Specialty Steel Industry of North America regularly highlights its significant role in infrastructure that supports daily life, from energy grids to bridges and urban transport. As industries expand and aging infrastructure needs renewal, stainless steel continues to serve as a durable solution, ensuring sustainable growth and public safety.

Breakthroughs in Stainless Steel Technology

Over the past decade, advancements in alloy design and manufacturing processes have unleashed new possibilities for stainless steel products. Novel processing techniques like powder metallurgy, additive manufacturing (3D printing), and advanced heat treatment have allowed engineers to customize alloy compositions and microstructures to fit highly specialized requirements. As a result, industries can now procure stainless steel parts that are stronger, lighter, and more resistant to modern production or transportation stresses.

Automation in production is also playing a transformative role. Modern manufacturing plants integrate sensor technology and digital monitoring into stainless steel machinery to maximize operational uptime. Connected machines can detect early signs of wear, prompting preventive maintenance and minimizing unexpected breakdowns. This integration of smart systems into manufacturing architectures leads to a more efficient use of raw materials and energy, supporting both operational profitability and long-term sustainability for manufacturers and their clients.

Sustainability and Green Manufacturing Initiatives

Sustainability has become a defining priority for manufacturers worldwide, exerting pressure to minimize waste and reduce environmental footprints. Stainless steel’s ability to be recycled almost endlessly without loss of quality places it among the greenest industrial materials available. Industry analysts estimate that nearly 90% of end-of-life stainless steel products are recycled. This reduces the need for new raw materials and leads to significant energy and cost savings for businesses and communities alike.

Recent industry shifts focus on producing “green steel”—stainless steel designed and manufactured with renewable energy, responsible sourcing, and lower emissions. The World Stainless Association reports rapid advancements in this realm, showing how ambitious initiatives are achievable and rapidly taking hold among key producers. As governments and corporations set more ambitious climate targets, the demand for green-certified, responsibly produced stainless steel solutions will only intensify in the coming years.

Expanding Applications Across Industries

The reach of stainless steel keeps broadening in today’s marketplace. In the medical field, precise stainless steel alloys are the backbone of sterile instruments and surgical implants, thanks to their stellar biocompatibility and resistance to contamination. Energy producers depend on stainless steel for pipelines and tanks that can endure corrosive fuels or steam for decades. Even wind and solar farms, which must brave unpredictable weather, turn to specialized stainless steel fasteners and frames as reliable, low-maintenance solutions for protecting critical equipment and maximizing returns.

The tech sector is another surprising adopter. As digital infrastructure expands, stainless steel solutions are employed in data center cooling systems and telecommunications equipment protective housings. In the food and beverage industry, corrosion-resistant stainless steel ensures sanitization and taste integrity, helping businesses comply with stringent safety standards. Engineers find new reasons to trust stainless steel to keep systems running safely and efficiently wherever you look.

Meeting Industry Standards and Compliance

Rigorous industry guidelines frame every stage of stainless steel production and implementation, particularly in pharmaceuticals, food processing, and clean energy sectors. Organizations often require stainless steel products that meet and exceed benchmarks for hygiene, stress tolerance, and chemical purity. Well-established standards from organizations like ASTM International and ISO form the baseline for quality, with further enhancements becoming the gold standard for global competition.

Achieving and maintaining certifications shows more than compliance; it’s evidence of a long-term investment in product safety, customer trust, and marketability. Continuous advancements in analytical tools and testing protocols ensure that stainless steel products are thoroughly assessed before reaching clients, keeping public health, safety, and consumer satisfaction at the forefront of manufacturing priorities.

Challenges Facing Stainless Steel Manufacturers

The stainless steel sector faces its share of challenges despite ongoing innovation. Price volatility for critical elements like nickel and chromium can introduce unpredictability and stress into production planning and supply contracts. In recent years, unpredictable geopolitical events and resource bottlenecks have amplified these risks, making swift adaptation and diversified procurement essential strategies for manufacturers.

Tightening local and international environmental regulations require manufacturers to invest in new technologies and update operational practices. Compliance with stricter emissions or energy efficiency laws can be costly initially, but those who innovate early often gain a crucial edge as competitors play catch-up. Navigating these market and regulatory challenges requires agility and a willingness to adopt new materials, technologies, and waste-reducing processes.

Predictions for the Next Decade

Looking ahead, stainless steel’s impact on manufacturing is only expected to increase. Industry analysts predict rapid growth in custom alloy development, enabling manufacturers to better match material properties to unique applications. 3D printing is expected to democratize the fabrication of complex stainless steel parts, increasing production flexibility and reducing lead times for specialized industries ranging from aerospace to luxury consumer goods.

Smart manufacturing—a seamless blend of intelligent automation, predictive analytics, and real-time performance feedback—will be increasingly powered by stainless steel components engineered for connectivity and longevity. As more sectors adopt green procurement policies and customers demand full lifecycle accountability, stainless steel will evolve to meet new challenges, combining tradition with forward-thinking innovation.

Practical Guidance for Industry Professionals

- Keep pace with technological advancements—new processes and alloys may offer opportunities for efficiency and competitive advantages.

- Work with suppliers and partners who commit to material quality and sustainable sourcing practices for long-term resilience and compliance.

- Regularly train staff in up-to-date methods for fabrication, inspection, and safety handling of stainless steel products.

- Monitor updates from industry associations and global regulators to prevent compliance gaps and maintain certifications.

- Harness data and analytics to guide purchasing, production, and maintenance, ensuring transparency and more intelligent business decisions.

Professionals who focus on continual improvement and strategic planning are best positioned to capitalize on stainless steel’s expanding role in shaping the future of manufacturing. Manufacturers and engineers can deliver safer, more reliable, and longer-lasting solutions for industries worldwide by adopting sustainable practices, embracing innovation, and maintaining stringent quality standards.

See Also: Theridgelinereport.com